For maximum resource efficiency, the accurate, continuous detection of level, volume or mass is essential. We have the right technology, be it Potentiometric, Hydrostatic, Differential Pressure ...

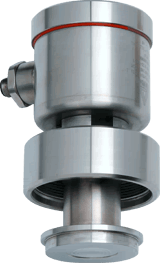

The new benchmark in level and pressure control, even with turndown and temperature changes. FOOD and PHARMA versions available

Temperature compensated transmitter for pressure control in pipes and vessels | With IO-Link

Temperature compensated transmitter for process pressure measurement in pipes and vessels

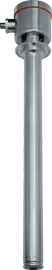

Level measurement in metallic tanks up to 140°C/284°F.

Potentiometric level sensor, Mini-version with bent rod, for precise continuous level measurement in metallic vessels

Level measurement in metallic tanks up to 140°C/284°F, straight and angled probe.

Process pressure measurement, sensor with metallic diaphragm up to 200°C/392°F

Hydrostatic level sensor with hermetically closed measuring cell, condensation proof, ideal for humid ambiance and exterior application in food processing

Hydrostatic level sensor with hermetically closed measuring cell, condensation proof, ideal for humid ambiance in pharma applications

Hydrostatic level sensor with hermetically sealed measuring cell fat the end of the rod for level measurement e.g. in underground tanks in food applications

Hydrostatic level sensor with hermetically sealed measuring cell fat the end of the rod for level measurement e.g. in underground tanks in pharma applications

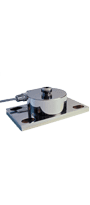

The Allrounder: Dynamic content monitoring through precise weight measurement, for all industrial applications

The Hygienic Specialist: Dynamic content measurement through precise weight measurement, polished design for all hygienic applications

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement, extremely robust design with cage

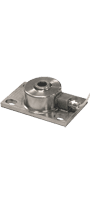

Bolt-on dual-axis shear force sensors for all types of vessels with metal supports and skirted silos

Bolt-on strain gauge sensors for vessels with metal substructures and skirted silos

The fully integrated all-in-one weighing system for all types of large containers and silos

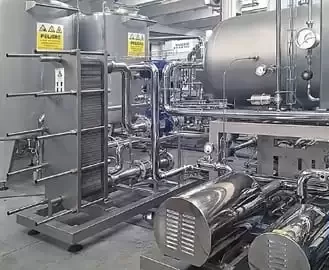

For efficient processes you must know much is in there: optimum production processes and maximum resource efficiency require continuous and accurate control of level, volume or mass in storage or process tanks. We have the most suitable level measurement technology for every medium, every tank type, and every application, be it hydrostatic, potentiometric, via weight measurement, or by differential pressure.

Discover our solutions below or in our White Paper “Hygienic, continuous level control technology –

Overview and criteria for selection”. Click here to download!

With a whole range of different pressure sensors, the most diverse requirements of hygienic applications for dairies, breweries, the beverage, and food industries can be covered. For the particularly high requirements of the pharmaceutical and life science industry, many models also exist in a special pharmaceutical version.

The range extends from the low-cost all-rounder P41 for standard applications through the P42, an identical model with IO-Link, to the high-end L3 model. The latter offers intelligent electronics with improved temperature compensation, density compensation for media and integrated tank linearization for different, specified or customer-specific container shapes. This allows direct output in liters, kg, BAR, or other units with significantly higher measurement accuracy than comparable devices. For outdoor applications or in cold or humid environments, the LAR can avoid measurement errors caused by climate-induced drift due to a special, hermetically welded measuring system.

The NSL measuring system is the core technology from which a comprehensive range of sensor variants is derived. This means that there are virtually no limits to the variety of applications:

In many applications, weighing systems for level detection offer a more practical and accurate solution than other measuring techniques. With a field-proven sensor program, Anderson-Negele also offers precise, robust and efficient solutions in this metrology range.

In many process vessels, storage tanks and silos, precise inventory control is a particular challenge. Classic instrumentation such as hydrostatic sensors, potentiometric probes or radar often reach their limits. In certain application environments, they are not precise, fast or flexible enough, not practical for technical reasons or not economical for cost reasons. The following systems are available. To provide a solution with weighing technology, following systems are available:

A number of factors influence the choice of technology:

The hydrostatic pressure is the pressure inside a liquid and always acts vertically towards all limiting walls of the container. As the level in such a vessel rises, so does the pressure. A sensor (transmitter) at the bottom of the vessel, can measure, display and output this pressure variations to the PLC. Since the pressure acts on all sides, the sensor diaphragm can be mounted at the bottom of the vessel or laterally at the bottom edge of the vessel, depending on which installation situation is more suitable.

To transmit the measurement results to the PLC, pressure transmitters use a piezoelectric signal converter internally, which converts the mechanical process pressure from the pressure diaphragm into a proportional voltage signal. This is then converted into a 4…20 mA standard signal or other protocol according to the customer’s adjustment.

Modern measuring systems, such as the L3, already offer the possibility of converting the measured pressure values in the sensor electronics and thus directly outputting volume or mass. For this purpose, further parameters must be determined, such as the container shape, the medium, and the process temperature (for the calculation of the respective specific density). In the case of the L3, the integrated temperature compensation provides a higher accuracy over the entire process temperature range than conventional hydrostatic level transmitters. This enables the display of the sensor in liters, kg, or other volume units with a very high measuring accuracy, even with dynamic temperature curves.

In an open system (vessel with atmospheric pressure), a pressure sensor at the bottom of the vessel is sufficient since the external pressure conditions do not change.

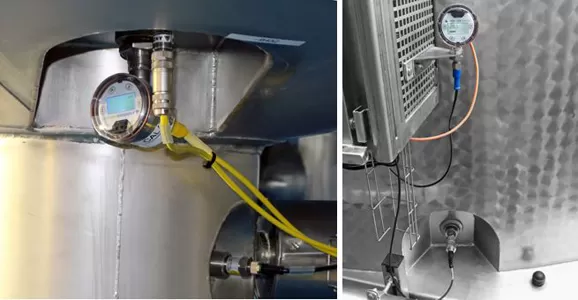

A closed system (pressure vessel), on the other hand, can be subjected to varying pressures, which affects the pressure at the bottom of the vessel. To measure the level in such a system, two sensors are required which separately determine the process pressure at the bottom and the head pressure at the top. The differential pressure can then be calculated from this in the PLC or an evaluation unit, and thus the correct fill level displayed.

The pressure sensor is installed in the vessel wall with the pressure diaphragm perpendicular to the vessel contents. The process or level pressure deforms the diaphragm. This deformation is transmitted by a transmitter fluid to a measuring cell with a piezoelectric signal converter, which converts the process pressure into a corresponding voltage signal. The electronics in the sensor head convert this in turn into the industry standard used, such as analog 4…20 mA or HART 7.0, according to the customer’s adjustment.

This allows the hydrostatic pressure to be output as an electrical signal to the PLC.

In relative pressure sensing elements, the back of the diaphragm is vented, so the sensor measures process pressure relative to atmospheric pressure.

In absolute pressure cells, the vacuum created during the manufacturing process remains between the diaphragm and the base body, i.e. the sensor measures the pressure relative to the vacuum.

Since the atmospheric pressure can change, e.g. due to meteorological influences, the measuring accuracy is generally higher for absolute measuring cells.

The L3 level sensor has been specially designed for measuring liquids in the food and beverage industry, where a high accuracy under dynamically changing temperature conditions is crucial for process control. This sensor uses a piezoelectric signal converter and an integrated temperature sensor to measure the pressure and temperature of the internal transfer fluid. The mV signal of the signal converter and the resistance of the temperature sensor are measured and converted to an adjusted pressure value by the signal electronics in the sensor nozzle.

This temperature compensation avoids measurement errors that are caused, for example, by the temperature effect or temperature drift: with changing temperatures, the specific density of a medium also changes, among other things. If this density is calculated for the level output at 20°C, but the process temperature is 80°C, then the measured value output is incorrect.

Conventional sensors show a temperature drift of up to 0.4% per 10°C. At 110 °C it is over 2.5%! The L3, on the other hand, shows a temperature drift of 0.03% per 10°C due to the reference on the calibrated measuring range. At 110°C, the temperature effect is less than 0.4%, i.e. six times lower.

Especially in humid environments or outdoors, problems such as drift phenomena or unstable measurements can occur with the hydrostatic measuring method using relative measuring cells due to condensate formation. In the so-called relative pressure measuring cells with compensation capillaries, a thin tube conducts the atmospheric pressure from the environment to the back of the measuring diaphragm. In sensors with diffusion-open double diaphragm, a separate pressure diaphragm is used for the atmospheric pressure and the hydrostatic pressure respectively. Both methods have a fundamental disadvantage: the diffusion of water vapor cannot be permanently prevented. Condensing water vapor can thus lead to sensor drift or fluctuating measured values.

In contrast, the LAR-361 hydrostatic level sensor is equipped with a hermetically welded measuring system. Ingress of gases and moisture is therefore impossible. The big difference here is that the atmospheric air pressure is recorded via a second measuring cell integrated in the sensor. This is hydraulically connected to the diaphragm of the process pressure measuring cell, which is in contact with the medium to be measured (e.g. milk). In damp and wet installation conditions, both indoors and outdoors, where conventional sensors can only be used to a limited extent and have a limited service life, sensors of this design represent a problem-free and reliably usable alternative.

The potentiometric measuring principle works with the change in the voltage ratio between the electrode rod of the sensor, which projects into the liquid, and the metallic wall of the filled tank. This value changes proportionally to the height of the medium in the tank itself, can be recorded with high precision and output as a measured value via the electronics. This measurement technique is only applicable for liquids with conductivity, at Anderson-Negele from <50μS/cm.

The potentiometric measuring method is suitable for closed and open process, feed and storage tanks as well as for pressurized tanks. For non-metallic tanks, a sensor variant with a reference rod can be used.

The sensor consists of an electronic unit and a measuring rod that protrudes into the liquid in the tank. Installation is possible from above, from below, diagonally and, thanks to a version with a bent measuring rod, also in the side wall of a tank. The length of the measuring rod can be precisely matched to the tank in 10 mm increments (intermediate sizes on request) up to a maximum of 3 m.

In the medium, the sensor generates an electric flow field, formed by the electrical conductivity and the capacitive properties. This creates a voltage ratio that is exactly proportional to the immersed part of the rod length. Since only the ratio of the voltages is considered, the properties of the medium, in particular the electrical conductivity, don’t influence the measurement result.

In the NSL, the sensor determines the immersion state of the electrode rod in the medium as additional information via a second measuring method. This is based on the evaluation of the electrical resonance properties and ensures that foam is detected and proportionally blanked out. Faulty measurements due to adhesion and foam are thus reliably avoided.

Due to the insensitivity to foam and buildup, the excellent measuring accuracy, and the extremely short response time, the measuring technology is suitable for a wide range of media and applications in dairies, breweries, milk and beverage processing companies, and in the food and pharmaceutical industries. The only basic requirements are the conductivity of the medium to be measured and the limitation to a container height of max. 3 m.

The flexible and modular NSL sensor system offers reliable and precise application even with difficult media and in demanding applications. Examples are:

The high-precision measurement process and intelligent electronics in the various NSL versions provide many different signal types:

The level measurement enables the setting of the following parameters:

Weighing systems for level detection offer a more practical and precise solution than other measuring techniques in many applications. With a field-proven sensor program, Anderson-Negele also offers precise, robust, and efficient solutions in this measuring range.

In many process vessels, storage tanks and silos, precise fill quantity determination is a particular challenge. Classical measuring systems such as hydrostatic sensors, potentiometric probes or radar often reach their limits. They are not precise, fast or flexible enough in certain application environments, not practical for technical reasons or not economical for cost reasons.

This is particularly the case with:

The solution: Turn your container into a precision scale. For more information, see the Weighing Systems product section.

Copyright © 2022 Anderson-Negele