Achieving maximum resource efficiency relies on precise, continuous detection of level, volume, or mass. Our advanced technologies—whether Potentiometric, Hydrostatic, Differential Pressure, or Weighing Systems—ensure optimal performance for every application.

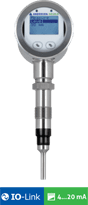

The benchmark for precision in level and pressure control, even with turndown and temperature changes. FOOD and LIFE SCIENCE versions available.

D3 Pharma Differential Pressure and Level Transmitter is the most complete electronic differential transmitter with best-in-class performance and dual mA output developed for Life Science Industry

The D3 is Anderson-Negele’s differential pressure/level transmitter for applications in food, dairy and beverage processing plants.

SL Level Transmitter by Anderson-Negele for accurate hygienic liquid level monitoring. 3-A compliant, easy calibration, ideal for inventory control and batching.

The NSL-F is the next generation of potentiometric technology. It is a direct replacement for the LN and offers additional features.

Probe type process level transmitter is the compact, high temperature alternative to the NSL-F

Hydrostatic level sensor for pasteurization balance tanks

Top down hydrostatic level transmitter for non-conductive liquids

Note: TD Level Transmitter is discontinued. HD Level Sensor is still available

Life Sciences series hydrostatic level transmitter for open vessels

The Liqui-Track 800 can be ordered with one or two input modules to accommodate four or eight tanks and multiple output options

Life Sciences series top down hydrostatic level transmitter

Bolt-on strain gauge sensors for vessels with metal substructures and skirted silos

Bolt-on dual-axis shear force sensors for all types of vessels with metal supports and skirted silos

The Hygienic Specialist: Dynamic content measurement through precise weight measurement, polished design for all hygienic applications

The Allrounder: Dynamic content monitoring through precise weight measurement, for all industrial applications

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement, extremely robust design with cage

High precision process pressure measurement in pipes & hydrostatic level and volume measurement in vessels

The fully integrated all-in-one weighing system for all types of large containers and silos

Achieving optimal production processes and maximizing resource efficiency requires precise and continuous monitoring of level, volume, or mass in storage and process tanks. Anderson-Negele offers advanced level measurement technologies tailored for various tanks, media, and applications. Whether you need hydrostatic, potentiometric, weight measurement, or differential pressure solutions, we have the right sensor for every need.

Discover our solutions below or in our White Paper “Hygienic, continuous level control technology –

Overview and criteria for selection”. Click here to download!

Anderson-Negele provides a comprehensive range of level sensors designed to meet the stringent demands of hygienic applications in industries such as dairy, brewing, food, and beverage. For the life sciences sector, we offer specialized pharmaceutical versions that cater to even higher requirements.

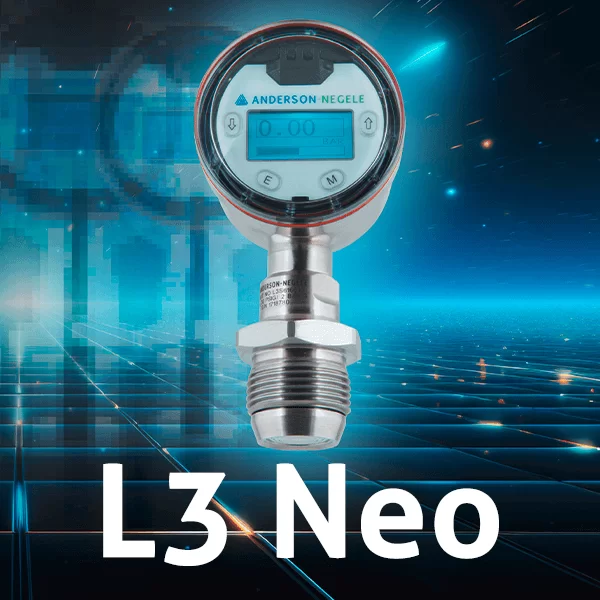

Our product lineup includes everything from the cost-effective P42 with IO-Link to the high-performance L3 model. The L3 features intelligent electronics with enhanced temperature compensation via an integrated temperature measuring cell, density compensation for various media, and integrated tank linearization for diverse or custom vessel shapes. This ensures highly accurate outputs in gallons, pounds, PSI, and other units, outperforming comparable devices. For outdoor or challenging environments, the LAR sensor prevents climate-induced drift with a hermetically sealed measuring system, ensuring reliable results. Additionally, our D3 Differential Pressure and Level Control sensor, based on the L3’s advanced technology, offers a solution with dual pressure detectors and integrated electronics for precise differential pressure output.

The NSL measuring system is the foundation of Anderson-Negele’s extensive range of potentiometric level sensors, designed to meet diverse application needs across various industries. This versatile technology allows for a wide array of configurations:

In many industrial applications, weighing systems offer a more practical and accurate solution for level detection compared to other measuring techniques. Anderson-Negele provides precise, robust, and efficient weighing solutions with a proven track record in the field.

Accurate inventory control in process vessels, storage tanks, and silos is often challenging. Traditional methods like hydrostatic sensors, potentiometric probes, or radar can sometimes fall short in terms of precision, speed, flexibility, or cost-effectiveness. Anderson-Negele addresses these challenges with advanced weighing technology, offering the following systems:

Selecting the best technology for level measurement depends on various factors that influence performance and accuracy:

Hydrostatic level measurement relies on the pressure exerted by a liquid within a vessel, acting vertically on all walls. As the liquid level rises, so does the pressure. A sensor (transmitter) positioned at the bottom or lower edge of the vessel measures these pressure variations and transmits the data to the PLC (Programmable Logic Controller). Depending on the installation requirements, the sensor diaphragm can be mounted at the vessel’s bottom or laterally at the bottom edge.

Pressure transmitters use a piezoelectric signal converter to convert the mechanical pressure detected by the sensor diaphragm into a proportional voltage signal. This signal is then output as a 4…20 mA standard signal or another protocol based on the customer’s needs.

Modern systems, like the Anderson-Negele L3, enhance hydrostatic measurement by directly converting pressure values into volume or mass in the sensor electronics. This advanced capability requires input on factors such as container shape, medium, and process temperature to calculate specific density accurately. The L3’s integrated temperature compensation ensures higher accuracy across the entire process temperature range, enabling precise readings in gallons, pounds, PSI, or other units, even under dynamic temperature conditions.

For open systems (vessels with atmospheric pressure), a single pressure sensor at the bottom of the vessel suffices, as external pressure remains constant. In closed systems (pressurized vessels), varying pressures can affect the measurement. In these cases, two sensors are used: one to measure the process pressure at the bottom and another to measure the head pressure at the top. The differential pressure between these two readings is calculated in the PLC or an evaluation unit, providing an accurate fill level.

How Does a Hydrostatic Pressure Transmitter Work?

A hydrostatic pressure transmitter operates by measuring the pressure exerted by the liquid within a vessel. The pressure sensor is installed in the vessel wall, with its diaphragm positioned perpendicular to the contents. As the process or level pressure increases, it deforms the diaphragm. This deformation is transmitted via a capillary fluid to a measuring cell equipped with a piezoelectric signal converter, which transforms the process pressure into a corresponding voltage signal.

The sensor’s internal electronics then convert this voltage into the industry-standard output, such as analog 4…20 mA or HART 7.0, depending on the customer’s requirements. This allows the hydrostatic pressure to be accurately output as an electrical signal to the PLC, enabling precise level monitoring and control.

What’s the Difference Between Relative and Absolute Pressure Gauges?

Relative pressure gauges measure the process pressure in relation to atmospheric pressure. In these sensors, the back of the diaphragm is vented, allowing the transducer to account for changes in atmospheric pressure. On the other hand, absolute pressure gauges measure pressure relative to a vacuum. During manufacturing, a vacuum is sealed between the diaphragm and the sensor’s base body, providing a stable reference point.

Because atmospheric pressure can fluctuate due to meteorological changes, absolute pressure gauges generally offer higher measurement accuracy, making them ideal for applications where precision is critical.

What is Temperature Compensation for Pressure Transmitters?

Temperature compensation is a critical feature for pressure transmitters, especially in industries like food and beverage where precision under fluctuating temperature conditions is essential. The Anderson-Negele L3 sensor is engineered for high accuracy in such environments, using a piezoelectric signal converter combined with an integrated temperature sensor. This setup measures both the pressure and temperature of the internal capillary fluid, ensuring accurate pressure readings.

The sensor’s electronics convert the mV signal from the converter and the resistance from the temperature sensor into an adjusted pressure value. This temperature compensation corrects for errors that can occur due to temperature effects or drift. For example, as temperatures change, the specific density of a medium also changes, which can lead to inaccurate level measurements if not properly compensated.

Conventional sensors may experience a temperature drift of up to 0.4% per 10°C, leading to significant inaccuracies at higher temperatures. At 110°C, this drift can exceed 2.5%. In contrast, the L3 sensor boasts a remarkably low temperature drift of just 0.03% per 10°C, resulting in a drift of less than 0.4% even at 110°C—six times lower than conventional sensors. This superior temperature compensation ensures highly accurate measurements, even in dynamic temperature environments.

Potentiometric level measurement relies on changes in the voltage ratio between the sensor’s electrode rod, which is immersed in the liquid, and the metallic wall of the filled tank. This voltage ratio changes proportionally with the height of the liquid in the tank, allowing for precise level detection. The measured values are then processed and output by the sensor’s electronics.

This measurement technique is specifically suited for liquids with electrical conductivity, typically at levels greater than 50μS/cm, as required by Anderson-Negele sensors. Potentiometric level measurement is versatile, making it ideal for use in both closed and open process tanks, feed tanks, storage tanks, and even pressurized tanks. For non-metallic tanks, a sensor variant with a reference rod is available to ensure accurate readings.

How Does a Potentiometric Level Sensor Work?

A potentiometric level sensor consists of an electronic unit and a measuring rod that extends into the liquid within the tank. The sensor can be installed in various positions, including from above, below, diagonally, or even in the side wall of a tank using a version with a bent measuring rod. The length of the measuring rod can be customized to fit the tank in 10 mm increments, up to a maximum of 3 meters, with intermediate sizes available upon request.

Once installed, the sensor generates an electric flow field within the liquid, influenced by the medium’s electrical conductivity and capacitive properties. This creates a voltage ratio that is directly proportional to the immersed portion of the rod. Since the sensor focuses solely on the voltage ratio, the medium’s properties, such as electrical conductivity, do not affect the measurement accuracy.

Anderson-Negele’s NSL sensors take accuracy a step further by utilizing a second measurement method. This method evaluates the electrical resonance properties to determine the exact immersion state of the electrode rod. It also effectively detects and compensates for foam, preventing erroneous readings caused by foam or adhesion. This ensures reliable and precise level measurement, even in challenging conditions.

Products and Applications Suitable for Potentiometric Level Measurement

Potentiometric level measurement is ideal for a wide range of media and applications, thanks to its insensitivity to foam and buildup, exceptional measuring accuracy, and extremely short response times. This technology is particularly well-suited for dairies, breweries, milk and beverage processing, as well as the food and life science industries. The primary requirements are the electrical conductivity of the medium and a container height of up to 3 meters.

The flexible and modular NSL sensor system ensures reliable and precise measurements, even in challenging conditions and demanding applications, including:

Signals and Parameters for Potentiometric Measurement

The NSL sensor system’s high-precision measurement process, combined with intelligent electronics, offers various signals and adjustable parameters:

Output Signals:

Adjustable Parameters:

In many applications, weighing systems offer a more practical and precise solution for level detection compared to other measurement techniques. Anderson-Negele provides robust, efficient, and field-proven weighing systems that excel in scenarios where traditional methods fall short.

Accurate fill quantity determination in process vessels, storage tanks, and silos is often challenging. Classical measurement systems like hydrostatic sensors, potentiometric probes, or radar may not be precise, fast, or flexible enough for certain environments. They can also be impractical due to technical limitations or cost constraints.

By implementing weighing systems, you can transform your container into a highly accurate scale, ensuring precise inventory measurement and control. For more details, visit the Kistler-Morse Website and explore their Weighing Systems product section.

Copyright © 2022 Anderson-Negele