- Login

- Find Distributor

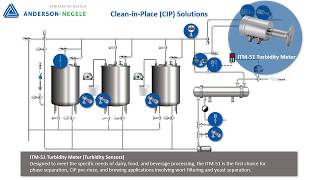

Clean-In-Place (CIP) Optimization with Sensor Technology

Clean-In-Place (CIP) is a standard application in many production plants in the beverage and food industries. In specific applications, steam sterilization (Sterilization In Place - SIP) complements the process. CIP process technology enables fast and efficient cleaning of production equipment without dismantling the components. As a result, this technique offers significantly less labor, reduces production downtime, and protects employees from direct contact with aggressive cleaning chemicals.

Technologies Details

Conditions for efficient and reproducible CIP-cleaning

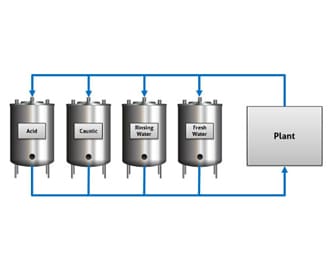

In CIP cleaning, all elements of the production equipment, i.e., tanks, pipes, and process lines, with all built-in components such as valves, pumps, or sensors, are cleared of product residues, residues of cleaning chemicals, microbes, bacteria, or other substances by a process involving a multistep cleaning system with different rinsing and cleaning liquids. A new production process can start immediately after the CIP process.

CIP cleaning quality can be monitored by inline analysis or sampling after each intermediate step and at the end of the overall process.

The CIP process costs can be reduced by different factors such as:

Sanitary sensors can help to increase the degree of automation and thereby

Maximum CIP cleaning efficiency is typically achieved by using the following types of sensors:

The CIP process

A CIP cleaning process consists of several coordinated steps. In general, these are

First, the product in the plant is pushed out with water or projectiles (pigging) and deposits are removed during pre-rinsing. In the further steps, organic residues are eliminated by means of caustic, and mineral deposits are removed by the use of acid. Intermediate and final steps are flushing with water.

The duration, intensity and temperature of the individual cleaning steps depend on many factors, such as the chemical properties and viscosity of the products, whether only one or several alternating products are run in a system, the technical properties of the system (e.g. tank size, tube diameter, pipe length, etc.) and production-specific devices in the process (e.g. heater, filter, spray nozzles, etc.).

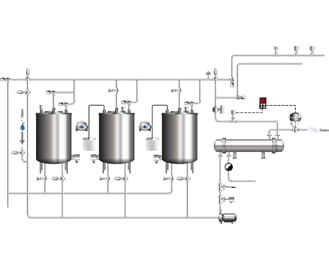

Often, the process is controlled through predetermined, pre-calculated process parameters. The pressure and thus the flow rate, the temperature and the duration of each process step and the corresponding control of the valves and pumps are programmed into the PLC and then run automatically. Such a passive control for the CIP process must take into account the above factors individually. To avoid defective results and to achieve the required cleaning quality, time buffers and safety margins must be provided between each individual step. This extends the overall duration and also leads to resource losses due to changeovers that are too early or too late, i.e., too much product or chemicals can go down the drain.

Analytical sensors in the CIP process

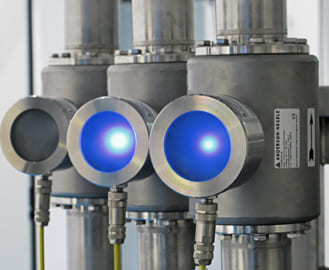

Analytical sensors such as turbidity or conductivity meters, your "eye in the pipe", measure the quality of the liquids inline and continuously, thus enabling active control in real time, based to the momentary circumstances.

You can precisely control at any moment

This allows for

CIP process control

Each step in the CIP-SIP process must be precisely controlled for reproducible and documentable cleaning. The process conditions must be rigorously monitored continuously. The corresponding sanitary sensors for temperature and pressure, flow meters and flow switches are available from Anderson-Negele in a wide range for individual installations and analog and digital communication systems such as IO-Link.

Monitoring of the detergent concentration

For optimum and reproducible cleaning results, each acid and each caustic must be concentrated to the specified value by dosing with concentrate and freshwater. Depending on the application, this is approx. 0.5 to 1.5 % for caustic solutions and 0.5 to 1.0 % for nitric acid solutions and can be precisely monitored via conductivity measurement. In this case, high measuring accuracy and resolution with simultaneous efficient temperature compensation play the most critical role for the sensor since the specified value of the concentration must be maintained extremely precisely for a verifiable cleaning result. This is ensured by the high accuracy conductivity measurement with the ILM-4 in a separate process line.

Application reports on CIP cleaning

Sensors for CIP installations

Videos

Clean in Place Process Optimization by Anderson Negele sensors

Copyright © 2022 Anderson-Negele