Automized phase transition is essential for many production and filling processes and for controlling the quality and concentration of CIP systems. Short response times below 1,2 seconds, superior accuracy and quality are ...

Integral (all in one) Inductive sensor-transmitter used for in-line measurement of process liquid conductivity. Now available with IO-Link capability.

The food and beverage industry often relies on measuring the conductivity of products and CIP (cleaning in place) media to accurately detect and differentiate liquids in the process. This technique is particularly useful for maintaining sanitary inline conditions. Additionally, it is also essential for controlling the concentration of CIP cleaning agents and automatically diluting them.

The superior process efficiency is based on three essential performance characteristics of the ILM-4 Sanitary Inline Conductivity Sensor:

The inline analysis of media based on their conductivity values enables automated, high-precision operation in many applications. These are primarily product differentiation, phase separation, process control and concentration control of CIP agents.

Product differentiation: the distinction of liquids within one second ensures the correct processing, storage or filling of products, such as:

Phase separation: the continuous media analysis enables real-time inline CIP control.

Process control: by continuously measuring the conductivity value, a deviation of the actual value from the specified target value can be detected with very high accuracy and immediately signaled.

CIP media concentration control: For an optimal and reproducible cleaning result, each cleaning agent must be adjusted to the specified value by re-dosing with concentrate and fresh water. This is ensured by the highly precise conductivity measurement with the ILM-4 in a separate process line.

Differentiating products is often not easy in practice, but it can make all the difference to the quality of the end product and the efficiency of the process. Still frequently used possibilities for product control, e.g. when filling different juices, are manual sampling or monitoring via a sight glass. However, experience shows that both of these methods involve high personnel costs and uncertainties in quality between samples.

Another common option for certain applications such as CIP cleaning is the time-controlled phase transition. However, a safety buffer of several seconds is needed to ensure that no incorrect product or cleaning chemicals such as acid or caustic get into the product tanks. This leads to additional expenses in each phase transition, as many liters of valuable product or cleaning agent are lost in the wastewater.

The Anderson-Negele ILM-4 Conductivity Meter, which is directly integrated into the process, can automate the phase transition with a very high degree of measuring accuracy. This avoids the loss of resources due to incorrect or delayed media changeover and saves money by avoiding personnel costs caused by visual or manual control. In many practical cases, the use of an Anderson-Negele conductivity sensors have paid for itself within a very short time.

The electrolytic conductivity of liquids is the property of conducting electric current. This is based on the fact that salts, acid and caustic molecules, when dissolved in the liquid, split up into positive and negative ions. This conductivity is measured in Siemens per meter (S/m) or, in finer gradations, in milliSiemens per centimeter (mS/cm) or MicroSiemens per centimeter (μS/cm). Different liquids have different conductivity values and can thus be precisely distinguished from one another, even if other properties such as color, turbidity or sugar content do not allow this.

There are basically two measuring methods available for the conductivity measurement of liquids: conductive (or contacted) conductivity measurement and inductive conductivity measurement.

Conductive conductivity probes have two or four electrodes on the sensor tip that are in direct contact with the medium. Anderson-Negele does not offer this measuring technique for applications in the food industry, since the measuring accuracy is negatively affected by deposits of salts, fat particles or crystals of the products on the exposed electrodes.

The ILM-4 is specifically designed for sanitary applications and is based on inductive conductivity measurement, thus ensuring a permanent and precise measurement in all applications and for all media.

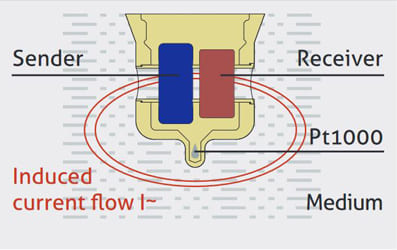

Inductive conductivity measurement involves two electrical coils integrated into the sensor tip. The primary coil generates an alternating magnetic field, inducing a current in the medium. This current creates a magnetic field that induces a voltage in the secondary coil, which is measured to determine the medium’s conductivity.

In the ILM-4 sensor, both coils are housed in a solid PEEK sensor tip. The medium flows through an opening in the tip, allowing analysis without direct contact, thus avoiding contamination. A Pt1000 temperature sensor is also integrated, continuously recording the medium’s temperature and compensating for temperature-related conductivity changes. The ILM-4 outputs both a precise, temperature-compensated conductivity value and an accurate temperature reading, eliminating the need for a separate temperature sensor.

Key advantages of this technique include easy inline integration into pipes and containers, a competitive price-performance ratio, and compliance with international hygiene standards like 3-A and EHEDG. The ILM-4 can be retrofitted into existing pipes from DN40 upwards.

Flex-Hybrid technology in the ILM-4 sensor allows data transmission through both digital (IO-Link) and analog (4-20mA) interfaces, either separately or simultaneously. This flexibility is crucial during the transition from analog to digital systems. With Flex-Hybrid, there’s no need to choose between technologies—simply connect a new cable to switch to digital without altering hardware or settings. This approach saves time and costs during installation and commissioning. Signal transmission and power supply are handled by a standard three-pole cable without shielding.

Two installation lengths for different pipe diameters and a large number of different process adaptations ensure maximum flexibility with regard to installation in new plants and retrofitting in existing processes. The compact ILM-4 can be easily integrated into pipes or containers via sanitary screw or clamp adaptations. Adapters are also available for existing process connections. A remote version is also available, which ensures optimum adaptation to local and technical conditions.

Copyright © 2022 Anderson-Negele